Maintmaster Manufacturing Intelligence (MI) helps manufacturers unlock the hidden value within their production data. It transforms everyday notes, shift comments, and work orders into structured, reliable insights that drive genuine operational improvement.

Built specifically for manufacturing environments, MI bridges the gap between production and maintenance. It interprets the shorthand and informal language used on the shop floor, detects recurring issues, and highlights the root causes of losses that traditional systems often overlook.

With Maintmaster MI, you can:

Identify and prioritise your biggest downtime drivers using Pareto-ranked loss analysis.

Access suggested actions based on previous successful fixes, helping teams solve problems faster.

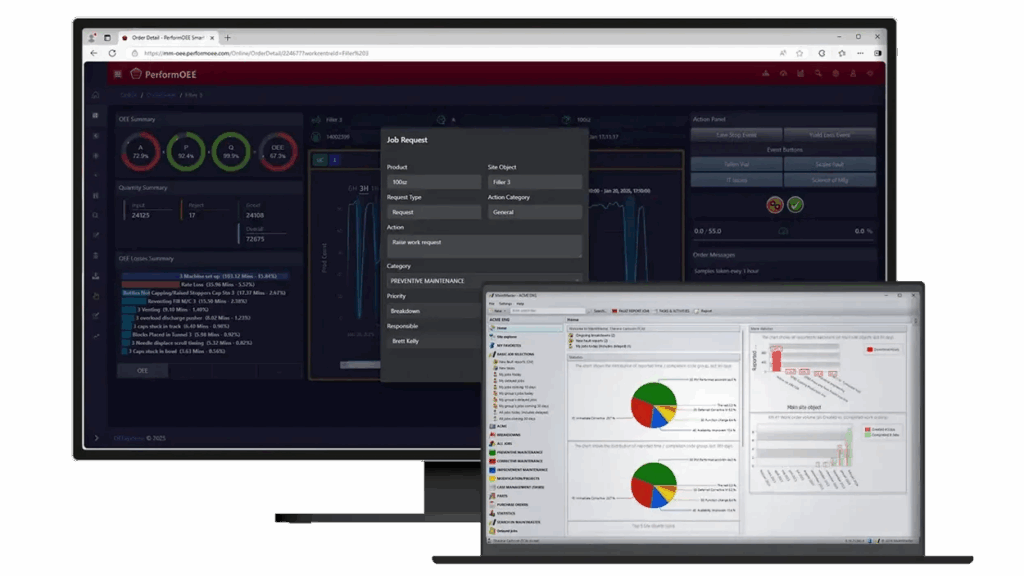

Combine production and maintenance data for a complete, real-time picture of performance.

Turn operator knowledge into measurable improvement for every line, site, and shift.

The software integrates seamlessly with your existing CMMS and OEE systems, creating a unified data foundation for continuous improvement. Its intuitive dashboards help maintenance teams, operators, and managers see exactly where time and resources will make the biggest impact.

Maintmaster MI does not just collect information—it gives meaning to it. By turning unstructured text into actionable insight, it empowers your people to make smarter decisions, prevent recurring problems, and boost overall equipment effectiveness.

Turn your shop floor knowledge into a competitive advantage with Maintmaster Manufacturing Intelligence.